Logon T.L., Mavor M.J., Khodaverdian M.

Optimizing and Evaluation of Open-Hole Cavity Completion Techniques for Coal Gas Wells. / 9346. -

The 1993 International Coalbed Methane Symposium (May 17-21, 1993, Birmingham-Jefferson Civic Center, Birmingham, Alabama, U.S.A). Volume 2. - Alabama: University of Alabama, 1993. - pp.609-622.

Logon T.L., Mavor M.J., Khodaverdian M.

Optimizing and Evaluation of Open-Hole Cavity Completion Techniques for Coal Gas Wells. / 9346. -

The 1993 International Coalbed Methane Symposium (May 17-21, 1993, Birmingham-Jefferson Civic Center, Birmingham, Alabama, U.S.A). Volume 2. - Alabama: University of Alabama, 1993. - pp.609-622.

ќЌ—ѕ≈ “: лючевое слово - self-propped fractures (само-поддерживающийс€ процесс разрушени€).

ABSTRACT

ABSTRACT

An innovative completion technique that has been used to

effectively complete coal gas wells is an open-hole

completion in which the coal is encouraged to slough into

the wellbore. During the completion process, the wellbore

is effectively linked to the reservoir due to the creation of

numerous multi-directional self-propped fractures. The

technique has been commonly called an "open-hole cavity

completion." However, the cavity is a by-product of the

process and not the primary objective of the completion. A

more suitable terminology for the technique is "dynamic

open-hole completion." The majority of the dynamic open-

hole completions have been performed in the Fruitland

Formation of the San Juan Basin, Colorado and New

Mexico. Dynamic open-hole completed coal gas wells in

some areas, but not all, produce at significantly greater

rates than wells completed using other techniques such as

hydraulic fracturing. Because of the success in the San

Juan Basin, dynamic open-hole completions have been

attempted in other basins including the Piceance, Powder

River, Arkoma, Uinta, and Black Warrior. This paper

presents a conceptual model and a working hypothesis

concerning what takes place in the coal reservoir during

the dynamic open-hole completion process. Based upon

this model and hypothesis, techniques to: i) optimize the

completion, ii) evaluate the effectiveness of the technique,

and iii) how to determine when to terminate completion

operations will be presented.

INTRODUCTION

Coal natural gas wells typically require stimulation

resulting in effective wellbore to reservoir linkage to

achieve economic gas production rates. The objective of a

dynamic open-hole completion is to: i) effectively link the

open-hole wellbore with the undamaged reservoir, ii)

create multi-directional self-propped fractures in the

reservoir, and iii) to intersect the natural fracture systems

within the coal. A by-product of the dynamic open-hole

completion procedure is an enlarged wellbore caused by

multiple pressure surges that encourage the friable and

relatively low strength coal to slough into the wellbore. In

this process, near wellbore damage is removed, multi-

directional self propped fractures

Coal natural gas wells typically require stimulation

resulting in effective wellbore to reservoir linkage to

achieve economic gas production rates. The objective of a

dynamic open-hole completion is to: i) effectively link the

open-hole wellbore with the undamaged reservoir, ii)

create multi-directional self-propped fractures in the

reservoir, and iii) to intersect the natural fracture systems

within the coal. A by-product of the dynamic open-hole

completion procedure is an enlarged wellbore caused by

multiple pressure surges that encourage the friable and

relatively low strength coal to slough into the wellbore. In

this process, near wellbore damage is removed, multi-

directional self propped fractures

are created, and the

enlarged wellbore may become linked to the natural

fracture system within the reservoir. During the open-hole

completion process, it is hypothesized that failure occurs

in the coal due to shear and tensile stresses creating

numerous multi-directional tensile, shear and extension

fractures. These fractures stimulate production by

effectively linking the wellbore to a large pre-existing

natural fracture surface area within the coal gas reservoir.

are created, and the

enlarged wellbore may become linked to the natural

fracture system within the reservoir. During the open-hole

completion process, it is hypothesized that failure occurs

in the coal due to shear and tensile stresses creating

numerous multi-directional tensile, shear and extension

fractures. These fractures stimulate production by

effectively linking the wellbore to a large pre-existing

natural fracture surface area within the coal gas reservoir.

/p.609/

The tensile failure mechanism is a result of the injection

process where the wellbore pressure is increased to a

pressure greater than the minimum wellbore stress

concentration near the well and the minimum principal

stress away from the wellbore in the coal. The orientation

of the tensile failure zone is parallel to the maximum

horizontal stress direction and the zone contains

numerous connected parallel fractures. These tensile

failure induced fractures may become self-propped.

The tensile failure mechanism is a result of the injection

process where the wellbore pressure is increased to a

pressure greater than the minimum wellbore stress

concentration near the well and the minimum principal

stress away from the wellbore in the coal. The orientation

of the tensile failure zone is parallel to the maximum

horizontal stress direction and the zone contains

numerous connected parallel fractures. These tensile

failure induced fractures may become self-propped.

Also during the injection period, the increase in pore pressure

near the wellbore causes the wellbore to decrease in size.

The decrease in the wellbore diameter may result in a

stress reduction away from the wellbore and cause tensile

failure initiation away from the well in multiple

directions. [11] It is hypothesized that these tensile

fractures may extend 30 to 60 m (100 to 200 feet) from the

wellbore on each side of the wellbore. This hypothesis is

based upon limited laboratory data. Additional laboratory

and field research are needed for confirmation.

Also during the injection period, the increase in pore pressure

near the wellbore causes the wellbore to decrease in size.

The decrease in the wellbore diameter may result in a

stress reduction away from the wellbore and cause tensile

failure initiation away from the well in multiple

directions. [11] It is hypothesized that these tensile

fractures may extend 30 to 60 m (100 to 200 feet) from the

wellbore on each side of the wellbore. This hypothesis is

based upon limited laboratory data. Additional laboratory

and field research are needed for confirmation.

In contrast, shear failure is a result of active loading when

the wellbore pressure is depressed, as during the

production period of the completion operations or during

under-hydrostatically balanced drilling operations. In this

case, active shear failure zones are created that are

oriented perpendicular to the maximum horizontal stress

direction and perpendicular to the tensile failure zone

orientation. The concept of active shear failure is similar to

that for wellbore breakout which has been extensively

researched and documented in the literature. [12,13,14]

In contrast, shear failure is a result of active loading when

the wellbore pressure is depressed, as during the

production period of the completion operations or during

under-hydrostatically balanced drilling operations. In this

case, active shear failure zones are created that are

oriented perpendicular to the maximum horizontal stress

direction and perpendicular to the tensile failure zone

orientation. The concept of active shear failure is similar to

that for wellbore breakout which has been extensively

researched and documented in the literature. [12,13,14]

The fractures in the shear zone may also become self-

propped. Based upon laboratory measurements in

sandstone rock types, the shear zones may extend several

wellbore diameters or upwards of 7.5 m (25 feet) from the

wellbore. The orientation of the tensile and shear failure

zones is illustrated in Figure 1.

The fractures in the shear zone may also become self-

propped. Based upon laboratory measurements in

sandstone rock types, the shear zones may extend several

wellbore diameters or upwards of 7.5 m (25 feet) from the

wellbore. The orientation of the tensile and shear failure

zones is illustrated in Figure 1.

/p.611/

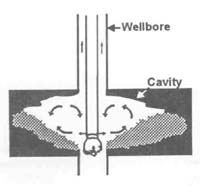

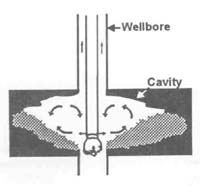

Techniques need to be developed to clean out the

wellbore more effectively and rapidly to reduce completion

costs. One technique that may increase the cleaning

efficiency is a side jetting tool placed in the drill string, as

shown on Figure 10. The objective of the jetting tool is to

create turbulent flow in the cavities where coal has

accumulated. During conventional clean out operations, air

and small slugs of water are circulated down the drill string

and up the annulus. The flow direction in the annulus is

vertical with the high velocities in the in-gauge wellbore

and low velocities in the cavities.

Techniques need to be developed to clean out the

wellbore more effectively and rapidly to reduce completion

costs. One technique that may increase the cleaning

efficiency is a side jetting tool placed in the drill string, as

shown on Figure 10. The objective of the jetting tool is to

create turbulent flow in the cavities where coal has

accumulated. During conventional clean out operations, air

and small slugs of water are circulated down the drill string

and up the annulus. The flow direction in the annulus is

vertical with the high velocities in the in-gauge wellbore

and low velocities in the cavities.

When the velocity of the

fluid decreases, rock particles transported by the fluid are

dropped at the base of the cavities. If the base of a cavity

is in a zone of high permeability, the cavity will be self

cleaning due to the inflow of water and gas from the

reservoir. However, if the base of the cavity is not in a

zone of high permeability, coal will accumulate in the

bottom of the cavity. This accumulation can block the

lower portion of the wellbore, as is illustrated in Figure 10.

When the velocity of the

fluid decreases, rock particles transported by the fluid are

dropped at the base of the cavities. If the base of a cavity

is in a zone of high permeability, the cavity will be self

cleaning due to the inflow of water and gas from the

reservoir. However, if the base of the cavity is not in a

zone of high permeability, coal will accumulate in the

bottom of the cavity. This accumulation can block the

lower portion of the wellbore, as is illustrated in Figure 10.

In addition, if the base of the cavity deteriorates, wellbore

cleaning and bridges at the base of the cavity become

more of a problem and will require additional time and

expense to remove. Therefore, the completion operations

should be terminated as soon as expected fluid production

rates are achieved and the wellbore is stabilized.

Extended operations typically result in increased wellbore

problems and costs, without enhancing fluid production.

In addition, if the base of the cavity deteriorates, wellbore

cleaning and bridges at the base of the cavity become

more of a problem and will require additional time and

expense to remove. Therefore, the completion operations

should be terminated as soon as expected fluid production

rates are achieved and the wellbore is stabilized.

Extended operations typically result in increased wellbore

problems and costs, without enhancing fluid production.

/p.615/

SUMMARY

Х The objective of a dynamic open-hole completion is to:

i) effectively link the open-hole wellbore with the

undamaged reservoir, ii) create multi-directional self-

propped fractures in the reservoir due to tensile and

shear failure, and iii) to intersect the natural fracture

system within the coal.

Х The objective of a dynamic open-hole completion is to:

i) effectively link the open-hole wellbore with the

undamaged reservoir, ii) create multi-directional self-

propped fractures in the reservoir due to tensile and

shear failure, and iii) to intersect the natural fracture

system within the coal.

Х The enlarged wellbore "cavity" is a by-product of the

operation and is not the primary cause of the increased

production rates observed.

Х The agreement between pre- and post-completion

permeability estimates has given us confidence in the

potential for estimating the applicability of dynamic

open-hole completions and the prediction of the post-

completion well performance based upon pre-

completion tests. Analysis of data that results in

estimates of the absolute permeability greater than 20

md suggests that dynamic open-hole completion

procedures can be used.

Х The agreement between pre- and post-completion

permeability estimates has given us confidence in the

potential for estimating the applicability of dynamic

open-hole completions and the prediction of the post-

completion well performance based upon pre-

completion tests. Analysis of data that results in

estimates of the absolute permeability greater than 20

md suggests that dynamic open-hole completion

procedures can be used.

Х Although dynamic open-hole completions have been

successful in some areas, the technique can be

improved, thereby enhancing the productivity, reducing

completion costs, and potentially broadening the

reservoir types where this technique can be

successfully applied.

Х One technique that may be used to complete multiple

coal seams is to increase the pore pressure and thus

the near wellbore stresses in the zone that is accepting

the air by initially injecting water ahead of the air

injection volume. The increase in the near wellbore

stress inhibits continued injection into the zone and

increases the ability to inject into other coal zones that

have not been affected by past injection/surges.

Х One technique that may be used to complete multiple

coal seams is to increase the pore pressure and thus

the near wellbore stresses in the zone that is accepting

the air by initially injecting water ahead of the air

injection volume. The increase in the near wellbore

stress inhibits continued injection into the zone and

increases the ability to inject into other coal zones that

have not been affected by past injection/surges.

Х The injected volume for each pressure/surge, should

be determined based upon the reservoir volume

required to i) pressurize the wellbore to create shear

failure, and ii) pressurize the fractured zones to

propagate the fractures. As the completion continues,

the fluid volume required increases due to the

increasing wellbore volume as the result of coal

sloughing.

Х The average total time required to complete a dynamic

open-hole completion operation is approximately 10

days at an average daily cost of approximately $8,000

($US) per day. During the completion operations, the

majority (65.2%) of the operation is spent cleaning out

the wellbore while only 22.3% of the total time is spent

conducting the injection/surges. Techniques need to be

developed to more effectively and timely clean out the

wellbore to reduce completion costs. One technique

that may increase the cleaning efficiency is a side

jetting tool placed in the drill string.

Х Generally, completion operations are discontinued

when successive injection/surge operations do not

result in increased fluid production rates. A more

quantitative approach is based upon estimates of the

fluid productivity of the reservoir once the wellbore and

the natural fracture system are linked.

/p.616/

© 05.02.2006 Ўестопалов ј.¬.

Logon T.L., Mavor M.J., Khodaverdian M.

Optimizing and Evaluation of Open-Hole Cavity Completion Techniques for Coal Gas Wells. / 9346. -

The 1993 International Coalbed Methane Symposium (May 17-21, 1993, Birmingham-Jefferson Civic Center, Birmingham, Alabama, U.S.A). Volume 2. - Alabama: University of Alabama, 1993. - pp.609-622.

Logon T.L., Mavor M.J., Khodaverdian M.

Optimizing and Evaluation of Open-Hole Cavity Completion Techniques for Coal Gas Wells. / 9346. -

The 1993 International Coalbed Methane Symposium (May 17-21, 1993, Birmingham-Jefferson Civic Center, Birmingham, Alabama, U.S.A). Volume 2. - Alabama: University of Alabama, 1993. - pp.609-622.

ABSTRACT

ABSTRACT

Coal natural gas wells typically require stimulation

resulting in effective wellbore to reservoir linkage to

achieve economic gas production rates. The objective of a

dynamic open-hole completion is to: i) effectively link the

open-hole wellbore with the undamaged reservoir, ii)

create multi-directional self-propped fractures in the

reservoir, and iii) to intersect the natural fracture systems

within the coal. A by-product of the dynamic open-hole

completion procedure is an enlarged wellbore caused by

multiple pressure surges that encourage the friable and

relatively low strength coal to slough into the wellbore. In

this process, near wellbore damage is removed, multi-

directional self propped fractures

Coal natural gas wells typically require stimulation

resulting in effective wellbore to reservoir linkage to

achieve economic gas production rates. The objective of a

dynamic open-hole completion is to: i) effectively link the

open-hole wellbore with the undamaged reservoir, ii)

create multi-directional self-propped fractures in the

reservoir, and iii) to intersect the natural fracture systems

within the coal. A by-product of the dynamic open-hole

completion procedure is an enlarged wellbore caused by

multiple pressure surges that encourage the friable and

relatively low strength coal to slough into the wellbore. In

this process, near wellbore damage is removed, multi-

directional self propped fractures

are created, and the

enlarged wellbore may become linked to the natural

fracture system within the reservoir. During the open-hole

completion process, it is hypothesized that failure occurs

in the coal due to shear and tensile stresses creating

numerous multi-directional tensile, shear and extension

fractures. These fractures stimulate production by

effectively linking the wellbore to a large pre-existing

natural fracture surface area within the coal gas reservoir.

are created, and the

enlarged wellbore may become linked to the natural

fracture system within the reservoir. During the open-hole

completion process, it is hypothesized that failure occurs

in the coal due to shear and tensile stresses creating

numerous multi-directional tensile, shear and extension

fractures. These fractures stimulate production by

effectively linking the wellbore to a large pre-existing

natural fracture surface area within the coal gas reservoir.

The tensile failure mechanism is a result of the injection

process where the wellbore pressure is increased to a

pressure greater than the minimum wellbore stress

concentration near the well and the minimum principal

stress away from the wellbore in the coal. The orientation

of the tensile failure zone is parallel to the maximum

horizontal stress direction and the zone contains

numerous connected parallel fractures. These tensile

failure induced fractures may become self-propped.

The tensile failure mechanism is a result of the injection

process where the wellbore pressure is increased to a

pressure greater than the minimum wellbore stress

concentration near the well and the minimum principal

stress away from the wellbore in the coal. The orientation

of the tensile failure zone is parallel to the maximum

horizontal stress direction and the zone contains

numerous connected parallel fractures. These tensile

failure induced fractures may become self-propped.

Also during the injection period, the increase in pore pressure

near the wellbore causes the wellbore to decrease in size.

The decrease in the wellbore diameter may result in a

stress reduction away from the wellbore and cause tensile

failure initiation away from the well in multiple

directions. [11] It is hypothesized that these tensile

fractures may extend 30 to 60 m (100 to 200 feet) from the

wellbore on each side of the wellbore. This hypothesis is

based upon limited laboratory data. Additional laboratory

and field research are needed for confirmation.

Also during the injection period, the increase in pore pressure

near the wellbore causes the wellbore to decrease in size.

The decrease in the wellbore diameter may result in a

stress reduction away from the wellbore and cause tensile

failure initiation away from the well in multiple

directions. [11] It is hypothesized that these tensile

fractures may extend 30 to 60 m (100 to 200 feet) from the

wellbore on each side of the wellbore. This hypothesis is

based upon limited laboratory data. Additional laboratory

and field research are needed for confirmation.

In contrast, shear failure is a result of active loading when

the wellbore pressure is depressed, as during the

production period of the completion operations or during

under-hydrostatically balanced drilling operations. In this

case, active shear failure zones are created that are

oriented perpendicular to the maximum horizontal stress

direction and perpendicular to the tensile failure zone

orientation. The concept of active shear failure is similar to

that for wellbore breakout which has been extensively

researched and documented in the literature. [12,13,14]

In contrast, shear failure is a result of active loading when

the wellbore pressure is depressed, as during the

production period of the completion operations or during

under-hydrostatically balanced drilling operations. In this

case, active shear failure zones are created that are

oriented perpendicular to the maximum horizontal stress

direction and perpendicular to the tensile failure zone

orientation. The concept of active shear failure is similar to

that for wellbore breakout which has been extensively

researched and documented in the literature. [12,13,14]

The fractures in the shear zone may also become self-

propped. Based upon laboratory measurements in

sandstone rock types, the shear zones may extend several

wellbore diameters or upwards of 7.5 m (25 feet) from the

wellbore. The orientation of the tensile and shear failure

zones is illustrated in Figure 1.

The fractures in the shear zone may also become self-

propped. Based upon laboratory measurements in

sandstone rock types, the shear zones may extend several

wellbore diameters or upwards of 7.5 m (25 feet) from the

wellbore. The orientation of the tensile and shear failure

zones is illustrated in Figure 1.

Techniques need to be developed to clean out the

wellbore more effectively and rapidly to reduce completion

costs. One technique that may increase the cleaning

efficiency is a side jetting tool placed in the drill string, as

shown on Figure 10. The objective of the jetting tool is to

create turbulent flow in the cavities where coal has

accumulated. During conventional clean out operations, air

and small slugs of water are circulated down the drill string

and up the annulus. The flow direction in the annulus is

vertical with the high velocities in the in-gauge wellbore

and low velocities in the cavities.

Techniques need to be developed to clean out the

wellbore more effectively and rapidly to reduce completion

costs. One technique that may increase the cleaning

efficiency is a side jetting tool placed in the drill string, as

shown on Figure 10. The objective of the jetting tool is to

create turbulent flow in the cavities where coal has

accumulated. During conventional clean out operations, air

and small slugs of water are circulated down the drill string

and up the annulus. The flow direction in the annulus is

vertical with the high velocities in the in-gauge wellbore

and low velocities in the cavities.

When the velocity of the

fluid decreases, rock particles transported by the fluid are

dropped at the base of the cavities. If the base of a cavity

is in a zone of high permeability, the cavity will be self

cleaning due to the inflow of water and gas from the

reservoir. However, if the base of the cavity is not in a

zone of high permeability, coal will accumulate in the

bottom of the cavity. This accumulation can block the

lower portion of the wellbore, as is illustrated in Figure 10.

When the velocity of the

fluid decreases, rock particles transported by the fluid are

dropped at the base of the cavities. If the base of a cavity

is in a zone of high permeability, the cavity will be self

cleaning due to the inflow of water and gas from the

reservoir. However, if the base of the cavity is not in a

zone of high permeability, coal will accumulate in the

bottom of the cavity. This accumulation can block the

lower portion of the wellbore, as is illustrated in Figure 10.

In addition, if the base of the cavity deteriorates, wellbore

cleaning and bridges at the base of the cavity become

more of a problem and will require additional time and

expense to remove. Therefore, the completion operations

should be terminated as soon as expected fluid production

rates are achieved and the wellbore is stabilized.

Extended operations typically result in increased wellbore

problems and costs, without enhancing fluid production.

In addition, if the base of the cavity deteriorates, wellbore

cleaning and bridges at the base of the cavity become

more of a problem and will require additional time and

expense to remove. Therefore, the completion operations

should be terminated as soon as expected fluid production

rates are achieved and the wellbore is stabilized.

Extended operations typically result in increased wellbore

problems and costs, without enhancing fluid production.

Х The objective of a dynamic open-hole completion is to:

i) effectively link the open-hole wellbore with the

undamaged reservoir, ii) create multi-directional self-

propped fractures in the reservoir due to tensile and

shear failure, and iii) to intersect the natural fracture

system within the coal.

Х The objective of a dynamic open-hole completion is to:

i) effectively link the open-hole wellbore with the

undamaged reservoir, ii) create multi-directional self-

propped fractures in the reservoir due to tensile and

shear failure, and iii) to intersect the natural fracture

system within the coal.

Х The agreement between pre- and post-completion

permeability estimates has given us confidence in the

potential for estimating the applicability of dynamic

open-hole completions and the prediction of the post-

completion well performance based upon pre-

completion tests. Analysis of data that results in

estimates of the absolute permeability greater than 20

md suggests that dynamic open-hole completion

procedures can be used.

Х The agreement between pre- and post-completion

permeability estimates has given us confidence in the

potential for estimating the applicability of dynamic

open-hole completions and the prediction of the post-

completion well performance based upon pre-

completion tests. Analysis of data that results in

estimates of the absolute permeability greater than 20

md suggests that dynamic open-hole completion

procedures can be used.

Х One technique that may be used to complete multiple

coal seams is to increase the pore pressure and thus

the near wellbore stresses in the zone that is accepting

the air by initially injecting water ahead of the air

injection volume. The increase in the near wellbore

stress inhibits continued injection into the zone and

increases the ability to inject into other coal zones that

have not been affected by past injection/surges.

Х One technique that may be used to complete multiple

coal seams is to increase the pore pressure and thus

the near wellbore stresses in the zone that is accepting

the air by initially injecting water ahead of the air

injection volume. The increase in the near wellbore

stress inhibits continued injection into the zone and

increases the ability to inject into other coal zones that

have not been affected by past injection/surges.